Industrial manipulators can deliver a wide range of benefits both to companies and their employees. These include:

- Improved ergonomics

In the UK alone, in 2017 work-related musculoskeletal disorders (WRMSDs) were attributed as the cause of 8.9 million working days lost. Manual material handling is one of the biggest causes of WRMSDs and can be prevented by the introduction of lift assist devices such as industrial manipulators.

- Increased productivity and greater precision

Output can be maintained continually throughout each shift, which enables increased productivity, without putting any stress or strain on the operator. With a sensitive response, operators are able to have complete control over the load, enabling precision load placement – which in turn reduces the risk of product damage.

- Safe material handling

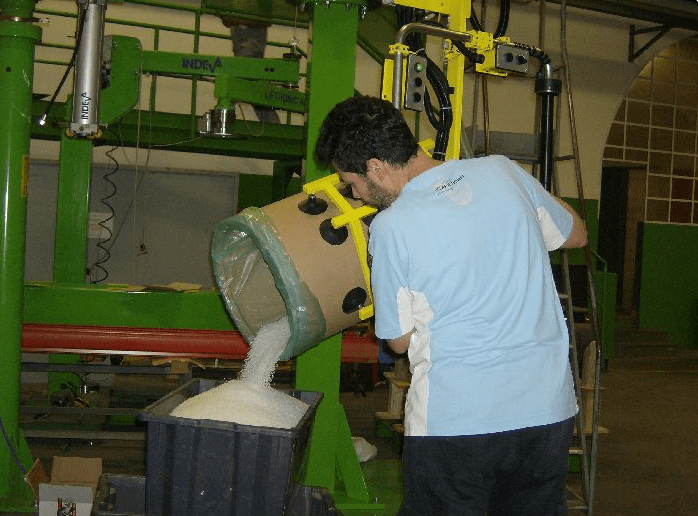

Gripping tools with vacuum suction cups or jaws make light work of handling delicate, heavy, or offset loads. In addition, state-of-the-art safety features means that – even in the event of an accident or power failure – the manipulator maintains grip until power is restored or the load is supported.

Scaglia Indeva®’s industrial manipulators, otherwise known as intelligent devices for handling (INDEVAs®) are equipped with a fingertip-sensitive handle which enables the operator to lift, lower and move heavy loads easily and effortlessly whilst allowing greater visibility of the work area. The float control mode enables the operator to have complete control with both hands placed on the load.

We understand the additional requirements that products used in the food manufacturing sector need to comply with. The Indeva®® meets the strict hygiene standards required by this industry – giving our customers peace of mind.

To find out more about our industrial manipulators for food manufacturing, please contact us on 01246 252333, or email info@uk.indevagroup.com.