World-class pneumatic manipulators from Indeva®

The Indeva® generation of pneumatic manipulators provide an intelligent and ergonomic lifting solution for production and assembly lines across a range of sectors – automotive, industrial, aerospace and food handling.

Unlike traditional manipulators, Indeva® utilises the latest technology to design and manufacture bespoke manipulators especially for their customers – with a large range of bespoke end gripping tools, this range of pneumatic manipulators can be tailored around your businesses exact requirements.

The purpose of the PN Series of pneumatic manipulators is to vastly improve material handling and workplace health & safety. Each manipulator employs state-of-the-art technology which provides flexible and precise movement for operators, reducing their risk of injury. In the event of air pressure reduction or loss. Indeva® manipulators will never drop a load. In fact, they’ll barely move, utilising their cutting-edge brake system which is built directly on the axis – the manipulator will wait for air pressure to be restored but in the meantime will slowly lower the load to the ground.

Indeva® pneumatic manipulators with bespoke end gripping tools

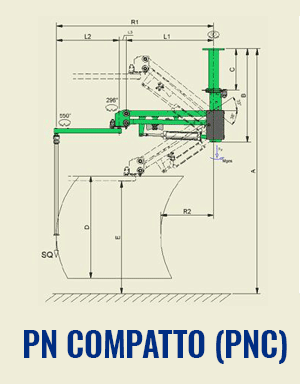

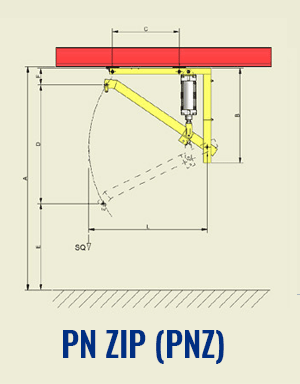

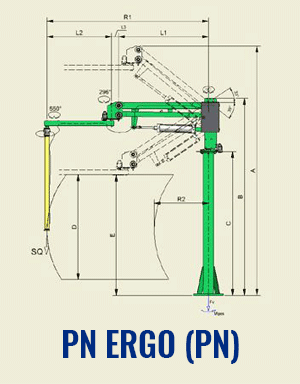

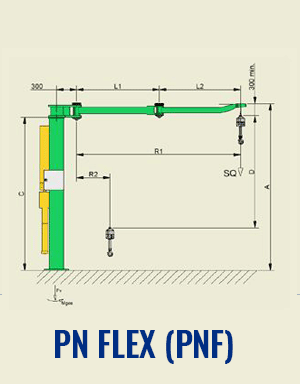

Our advanced PN series can be adapted for a range of applications and can be fitted with a range of bespoke end gripping tools. Installation options are floor mounted with column, permanent overhead fixing and mounted to an X-Y gantry system.

These reliable and robust manipulators can lift, travel, turn and position loads up to around 300kg easily and effortlessly with little exertion from the operator, meaning you can quickly improve overall workforce productivity.

PN series improving employee absenteeism and work-related injuries

What’s more, just like the Indeva® Liftronic® range, the PN series of pneumatic manipulators is designed to be intrinsically safe – they can help to reduce work-related musculoskeletal disorders caused by repetitive strain and continuous heavy lifting.