Turnkey Solutions

PalFlex

LoadFlex

Smart Robots

MoveFlex

MyWelder

Turnkey Solutions

Indeva Cobotics has developed a number of turnkey solutions that can help to transform manufacturing processes. They reduce the amount of time spent on repetitive manual tasks and create greater efficiency and productivity while enhancing overall health and safety for employees.

These revolutionary solutions have the potential to be game-changers, helping manufacturers innovate and develop.

PalFlex

PalFlex is a modular and easy to use palletising solution that’s ready to plug in and operate. With speeds of up to 14 pieces per minute, it’s able to palletise boxes, cans or other objects up to 16kg.

PalFlex allows for the managing of interlayers with the addition of a special warehouse module. Particularly high pallets can be created by means of a telescopic column. PalFlex is also unique in that it comes with its own dedicated palletising software.

LoadFlex

LoadFlex is an adaptable series of island loaders and automatic warehouses. They make it possible to speed up production processes, removing the time and labour spent on repetitive and monotonous tasks. LoadFlex helps to eliminate downtime, enabling both operators and machines to work to their maximum potential.

From automated loaders to compact warehouses and a revolving pallet warehouse, the LoadFlex series has been designed with the specific needs of the industry in mind.

Smart Robots

Smart Robots are a key example of how cobotics can help to transform the potential and productivity of human operators. This 3D intelligent vision device supports the operator in manual tasks. Quality Control guides and verifies the operator’s actions.

By reducing errors it also reduces costs, while standardising the process and improving the overall quality of the finished product. Human-Robot Collaboration can coordinate the operator’s activities, doubling their productivity, helping to avoid collisions while increasing quality and ergonomics.

MoveFlex

MoveFlex provides the possibility of integrating the Doosan Cobot with an INDEVA AGV. This integration allows for the handling of components over longer distances which, in effect, makes the cobot’s range of action unlimited.

The cobot can also be configured to perform different tasks along the way. Its vision system eradicates positioning problems while ensuring maximum flexibility in the system.

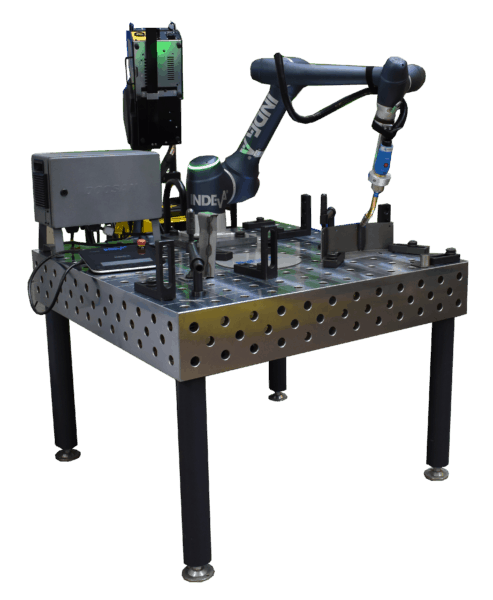

MyWelder

MyWelder is a highly adaptive, safe and precise welding station. It’s available for gas metal arc welding (MIG & MAG), and gas tungsten arc welding (TIG) and can be established for specific welding conditions. There is also a possibility to connect the welding equipment to the cobot and to communicate specific on/off points.

Find out more

If you have any questions or would like to find out more about any of our turnkey solutions, call 01246 252 333 email info@uk-indevagroup.co.uk or contact us online.